Factory Automation

Factory Automation

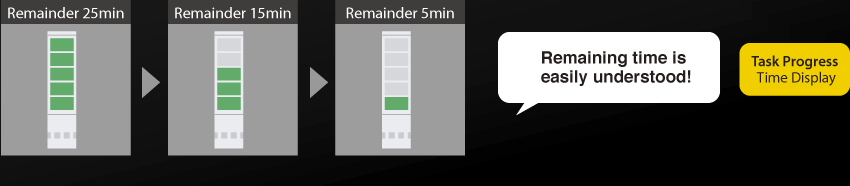

| Case 1 | Complete assembly lline progress management by making Takt time visible! | Operating Mode |  |

- Workers along the assembly line were not aware that they were completing tasks at different rates, causing the line to progress at various speeds.

- Now each worker along the line can know how much time is left to minimize delays and allow the line to flow more consistently.

■ Display remaining work time with the number of tiers

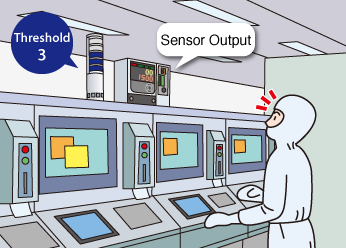

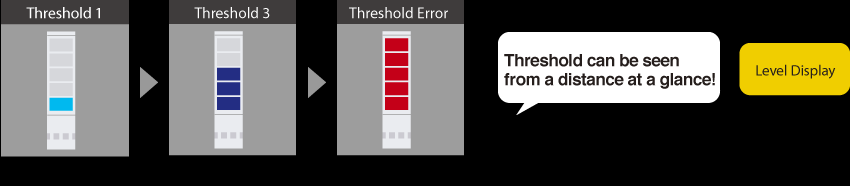

| Case 2 | Control management with visualization of analog equipment information and sensor feedback! | Operating Mode |  |

- Only circumstances of the equipment’s abnormal condition were displayed, but neither a threshold point nor elapsed time from an abnormal condition was understood.

- The threshold point is displayed in real time and can be seen from a distance. By including an elapsed time display, equipment priority can be grasped and prompt action can be made before abnormalities arise.

■ Threshold response turns to a memory display

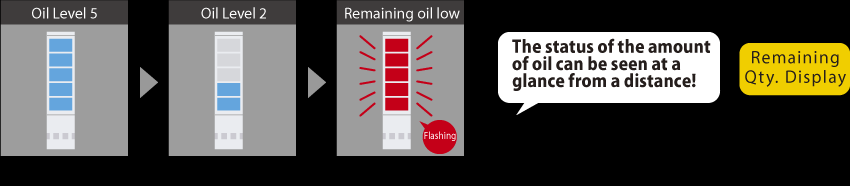

| Case 3 | Replenish cutting fluid in a timely manner by "seeing" how much is left | Operating Mode |  |

- When checking the capacity of the cutting-fluid tank, visual confirmation is made for the in-ground tank by installing floatation devices, but the time and effort to check has a delay.

- The amount of cutting fluid is made visible in real time and can be seen from a distance, which allows multiple machines to be monitored at a glance and appropriate responses can be made.

■ Remaining tank level indication

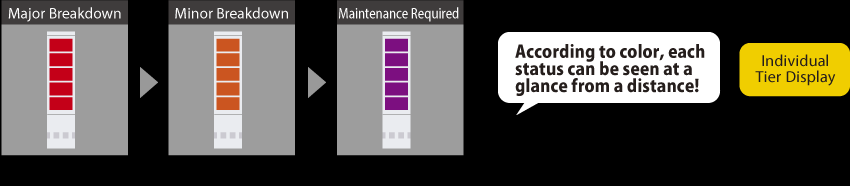

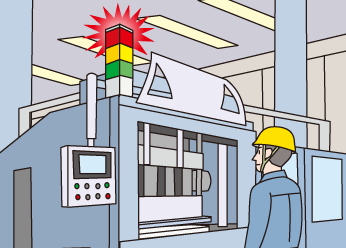

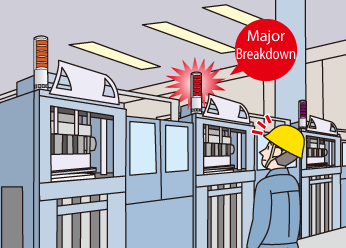

| Case 4 | Various machines can be monitored more precisely for abnormal conditions! | Operating Mode |  |

- Abnormalities for equipment was displayed and could be seen from a distance but its severity could not be determined unless extra time was taken to approach the machine.

- Now equipment can be checked for abnormalities at a glance from a distance, and when all tiers light up, prompt attention can be given.

■ All tiers light-up for abnormal conditions